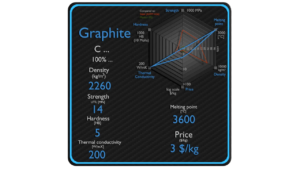

Graphite is a widely used carbon material valued for its thermal stability, electrical conductivity, and mechanical reliability. It plays a critical role in industries such as energy storage, metallurgy, aerospace, electronics, and chemical processing. Among its many physical characteristics, graphite density is one of the most important parameters for determining performance and suitability for specific applications.

This article explores graphite density in detail, covering its composition, typical density range, key influencing factors, and real-world industrial uses, while maintaining a balanced and SEO-optimized keyword strategy.

Understanding Graphite Composition

Graphite is an allotrope of carbon in which atoms are arranged in a layered hexagonal structure. These layers are held together by weak van der Waals forces, allowing them to slide easily over one another. This unique structure is responsible for graphite’s lubricating properties, electrical conductivity, and heat resistance.

However, graphite is not a perfectly solid material. Microscopic pores form during production, and the size and distribution of these pores directly affect graphite density. Both natural graphite and synthetic graphite differ in composition and internal structure, leading to variations in density and performance.

What Is Graphite Density?

Graphite density refers to the mass per unit volume of the material and is typically expressed in grams per cubic centimeter (g/cm³). It indicates how compact the graphite structure is and how much porosity exists within the material.

Higher graphite density generally means:

-

Lower porosity

-

Higher mechanical strength

-

Improved electrical and thermal conductivity

Lower-density graphite, on the other hand, may offer advantages in applications requiring lubrication or thermal insulation.

Typical Graphite Density Range

Graphite density is not a single fixed value. It varies depending on raw materials, manufacturing processes, and intended applications.

Common graphite density ranges include:

-

Natural graphite: 2.1 to 2.3 g/cm³

-

Synthetic graphite: 1.5 to 1.9 g/cm³

-

Isostatic graphite: 1.7 to 1.85 g/cm³

-

Extruded graphite: 1.6 to 1.75 g/cm³

-

Vibration-molded graphite: 1.65 to 1.8 g/cm³

These ranges allow engineers to select graphite grades tailored to performance needs such as strength, conductivity, or thermal resistance.

Factors Influencing Graphite Density

1. Raw Material Selection

The purity and particle size of petroleum coke or natural graphite flakes significantly affect packing efficiency, which influences final density.

2. Manufacturing Process

Forming techniques such as isostatic pressing, extrusion, and vibration molding determine how uniformly particles are compressed, directly impacting density consistency.

3. Porosity Control

Porosity reduces graphite density. For structural or chemical applications, manufacturers aim to minimize pore size and distribution.

4. Graphitization Temperature

Higher graphitization temperatures improve carbon crystal alignment, which can slightly increase density and enhance conductivity.

5. Binder Content

Binders used during shaping affect pore formation and shrinkage during heat treatment, influencing final density.

Relationship Between Graphite Density and Material Properties

Mechanical Strength

High-density graphite offers better compressive strength and wear resistance, making it suitable for mechanical and load-bearing applications.

Thermal Conductivity

Dense graphite transfers heat more efficiently, which is essential in high-temperature furnaces, heat exchangers, and thermal management systems.

Electrical Conductivity

As density increases, electrical conductivity improves due to reduced air gaps within the structure.

Chemical Resistance

Low-porosity, high-density graphite resists chemical penetration, making it ideal for corrosive environments.

Machinability

Graphite with balanced density provides excellent machinability, allowing precision shaping without cracking.

Real-World Uses of Graphite Based on Density

1. Energy Storage and Batteries

High-density graphite is widely used in lithium-ion battery anodes, where electrical conductivity and structural stability are critical.

2. Electrodes and Metallurgical Applications

Graphite electrodes for electric arc furnaces rely on high density to withstand extreme temperatures and electrical loads.

3. Refractory and High-Temperature Equipment

Dense graphite is used in crucibles, furnace linings, and heating elements due to its resistance to thermal shock.

4. EDM (Electrical Discharge Machining)

Graphite electrodes with uniform density ensure precision, smoother finishes, and longer tool life.

5. Mechanical Components

Bearings, seals, and bushings use graphite with optimized density for low friction and durability.

6. Aerospace and Nuclear Industry

High-purity, high-density graphite is critical in aerospace structures and nuclear reactors, where reliability and thermal stability are essential.

Choosing the Right Graphite Density

Selecting the correct graphite density depends on:

-

Operating temperature

-

Mechanical stress levels

-

Electrical or thermal performance requirements

-

Chemical exposure

-

Machining precision

Reviewing technical specifications and working with experienced graphite manufacturers helps ensure optimal performance and long-term reliability.

FAQs About Graphite Density

What is the average density of graphite?

Graphite density typically ranges from 1.5 to 2.3 g/cm³, depending on type and processing method.

Does higher graphite density mean better quality?

Not always. Higher density improves strength and conductivity, but some applications require controlled porosity and lower density.

How does graphite density affect thermal performance?

Higher density generally enhances thermal conductivity and resistance to heat-related degradation.

Is synthetic graphite less dense than natural graphite?

Yes. Synthetic graphite usually has lower density due to controlled porosity during manufacturing.

Can graphite density be customized?

Yes. Density can be adjusted through raw material selection, forming methods, and heat treatment processes.

Conclusion

Graphite density plays a defining role in determining the material’s mechanical strength, thermal behavior, electrical conductivity, and chemical resistance. By understanding graphite composition, density ranges, and the factors influencing density, industries can select graphite grades that meet specific operational demands.

From energy storage and metallurgy to aerospace and high-temperature processing, choosing the correct graphite density ensures efficiency, durability, and long-term performance. As industrial requirements continue to evolve, density-controlled graphite remains a cornerstone material in modern engineering and manufacturing.