India is witnessing rapid industrialization, urban growth, and technological advancement across sectors such as manufacturing, IT, metro rail, renewable energy, and smart cities. With this expansion, the demand for high-quality and reliable power infrastructure is at its peak. Among the essential components of electrical systems, power transformers play a critical role in voltage regulation, long-distance power transmission, and ensuring stable electricity flow. As a result, power transformer manufacturers in India have become central to building a secure and efficient national power grid.

🏭 Growth of Power Transformer Manufacturing in India

Over the last decade, India has transformed into a major hub for transformer production, supported by initiatives like Make in India and increasing investments in transmission and distribution (T&D) infrastructure. Indian transformer manufacturers now supply not only to domestic markets but also to more than 50 countries worldwide, including the Middle East, Africa, and Southeast Asia.

Improved engineering capabilities, automated production lines, and adherence to global certifications such as IEC, BIS, ISO, and CPRI approvals have helped Indian companies earn global recognition.

🔧 Importance of Power Transformers in Modern Electrical Networks

Power transformers are responsible for:

-

Stepping up voltage for long-distance transmission

-

Reducing losses in power systems

-

Maintaining balanced voltage levels across substations

-

Supporting grid stability and energy efficiency

Without high-performance transformers, industries, infrastructure, and public utilities would face frequent power failures, inefficiencies, and increased operational costs.

Over the last decade, India has transformed into a major hub for transformer production, supported by initiatives like Make in India and increasing investments in transmission and distribution (T&D) infrastructure. Indian transformer manufacturers now supply not only to domestic markets but also to more than 50 countries worldwide, including the Middle East, Africa, and Southeast Asia.

Improved engineering capabilities, automated production lines, and adherence to global certifications such as IEC, BIS, ISO, and CPRI approvals have helped Indian companies earn global recognition.

🔧 Importance of Power Transformers in Modern Electrical Networks

Power transformers are responsible for:

-

Stepping up voltage for long-distance transmission

-

Reducing losses in power systems

-

Maintaining balanced voltage levels across substations

-

Supporting grid stability and energy efficiency

Without high-performance transformers, industries, infrastructure, and public utilities would face frequent power failures, inefficiencies, and increased operational costs.

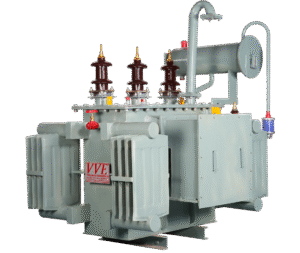

⭐ Key Features of Modern Power Transformers Manufactured in India

Today’s transformer designs incorporate advanced engineering, safety features, and durability enhancements, including:

-

Low-loss core materials (CRGO / Amorphous metal)

-

Copper or aluminium windings based on budget and performance needs

-

Advanced insulation systems for high thermal endurance

-

Digitally enabled monitoring systems (IoT-based smart transformers)

-

Eco-friendly transformer oils such as ester fluids

These technological upgrades ensure long service life, stable performance, reduced maintenance, and cost efficiency.

🏆 Leading Applications Across Multiple Sectors

Power transformers manufactured in India are widely used across:

-

Thermal, hydro, and nuclear power plants

-

Solar and wind renewable energy projects

-

Railways, metro networks, and airports

-

Petrochemical and refinery sectors

-

Steel, mining, and heavy machinery industries

-

Commercial complexes, data centers, and SEZs

With India’s growing focus on sustainability, hybrid and smart grid-ready transformers are increasingly becoming the preferred choice.

🔍 How to Choose the Right Power Transformer Manufacturer

With many manufacturers available, selecting the right partner is crucial. Consider:

| Evaluation Factor | Why It Matters |

|---|---|

| Technical certifications | Ensures compliance and safety |

| Manufacturing capacity | Determines product availability for large projects |

| Testing facilities | Guarantees long-term performance and reliability |

| Custom engineering capability | Supports industry-specific solutions |

| AMC and support service | Ensures operational continuity |

A reliable manufacturer not only supplies transformers but also offers installation, testing, maintenance, and lifecycle support.

🎯 Conclusion

Power transformer manufacturers in India are playing a crucial role in strengthening the nation’s power infrastructure and supporting industrial development. With improved technology, stricter quality standards, and a focus on energy efficiency, Indian manufacturers are emerging as global competitors in the electrical equipment industry.

As India continues its transition toward smart cities, renewable energy integration, and digital power monitoring, the demand for high-performance power transformers will continue to rise — making the role of trusted manufacturers more important than ever.