The electronics industry is entering a pivotal era where innovation must align with environmental responsibility. As demand for smarter devices accelerates, manufacturers and policymakers are rethinking material choices to reduce ecological impact without sacrificing performance. Bio-Based Materials for Smart and Sustainable Electronics are emerging as a transformative solution, reshaping how devices are designed, produced, and recycled across global value chains.

The sustainability challenge in modern electronics stems from heavy reliance on finite resources and complex supply chains. Traditional plastics, rare metals, and chemically intensive processes contribute to emissions, waste, and long-term environmental degradation. As regulations tighten and consumers grow more conscious, companies face mounting pressure to innovate responsibly. Business Insight Journal frequently explores how sustainability has shifted from a compliance issue to a core competitive advantage in technology markets.

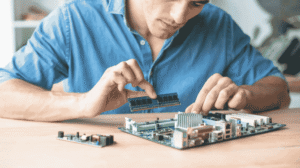

Bio-Based Materials for Smart and Sustainable Electronics represent a significant departure from petroleum-based inputs. Derived from renewable biological sources such as plant fibers, algae, cellulose, and bio-polymers, these materials offer comparable functionality with a reduced carbon footprint. Their adaptability allows integration into circuit boards, casings, flexible displays, and energy storage components. BI Journal analysis shows that advances in material science are closing performance gaps that once limited large-scale adoption.

Smart technologies benefit uniquely from bio-based innovation. Lightweight structures improve energy efficiency in portable devices, while flexible bio-polymers enable wearable and foldable electronics. Thermal stability and insulation properties can be engineered to meet demanding operational standards. As devices become more interconnected and data-driven, material efficiency plays a crucial role in overall system performance. Bio-based solutions support this evolution by enabling modular design and easier end-of-life processing.

Performance advantages are increasingly evident as research investment grows. Bio-composites can be tailored at the molecular level to enhance conductivity, durability, and resistance to environmental stress. This customization fosters design innovation, allowing manufacturers to rethink form factors and user experience. Electronics brands that adopt these materials early often position themselves as sustainability leaders, strengthening trust and long-term brand equity.

The economic implications extend beyond manufacturing. Local sourcing of bio-based inputs reduces exposure to volatile commodity markets and geopolitical risks. Rural and agricultural economies benefit from new value streams, creating more resilient supply networks. According to insights shared by Business Insight Journal, this decentralization aligns with broader trends toward regionalized production and circular economy models.

Environmental impact remains a central driver. Bio-based materials typically generate lower lifecycle emissions and support biodegradability or recyclability. While not all components can yet be fully organic, hybrid systems significantly reduce waste compared to conventional electronics. This progress supports corporate environmental goals and aligns with international climate commitments, making sustainability measurable rather than symbolic.

Strategic adoption requires collaboration across sectors. Material scientists, electronics engineers, policymakers, and investors must coordinate standards, certifications, and scalability efforts. Knowledge-sharing platforms and executive networks such as Inner Circle : https://bi-journal.com/the-inner-circle/ provide critical forums for aligning innovation with commercial realities. BI Journal emphasizes that leadership engagement accelerates responsible technology transitions.

Challenges remain, including cost parity, long-term durability testing, and consumer perception. However, economies of scale and continuous innovation are steadily addressing these barriers. As smart devices proliferate across healthcare, mobility, and infrastructure, the case for sustainable materials becomes stronger. Executives who integrate bio-based strategies into product roadmaps gain resilience against regulatory shifts and market disruption. There are still some problems with materials like making them cost the same as other materials testing if they will last a long time and what people think of them.. Companies are getting better at making a lot of these materials, which helps to lower the cost and they are always coming up with new ideas. As we see smart devices being used in healthcare in the way we move around and in the things we build it becomes clearer that we should be using sustainable materials. The people in charge who decide to use materials when they are planning new products will be better able to deal with changes in rules and unexpected problems in the market. Sustainable materials are getting attention and the case for using them is getting stronger. Executives who use bio-based strategies when they are planning their products will be more prepared, for shifts and market disruption.

For more info https://bi-journal.com/bio-based-materials-for-sustainable-electronics/

In conclusion, Bio-Based Materials for Smart and Sustainable Electronics are redefining the future of technology. They balance performance with responsibility, enabling smarter devices that respect planetary limits. As adoption expands, these materials will move from niche innovation to industry standard, shaping a more sustainable digital economy for decades to come.

This news inspired by Business Insight Journal: https://bi-journal.com/