Liquid silicone injection molding has emerged as a revolutionary process in modern manufacturing, combining precision, flexibility, and durability for a wide range of applications. This technique involves injecting liquid silicone rubber into meticulously designed molds under controlled temperature and pressure, resulting in high-quality components with consistent performance. Industries from medical devices to automotive and electronics increasingly rely on this process due to its ability to produce intricate shapes, complex geometries, and functional parts that meet strict standards.

The unique properties of liquid silicone rubber, including thermal stability, elasticity, and chemical resistance, make it ideal for high-performance applications. Liquid silicone injection molding allows manufacturers to produce components that maintain their shape, strength, and aesthetic appeal even under challenging conditions. From gaskets and seals to flexible housings, this process ensures that every part performs reliably throughout its lifecycle.

how liquid silicone injection molding enhances product quality

liquid silicone injection molding provides exceptional control over material flow and mold filling, which significantly improves product quality. The process minimizes defects such as voids, warping, or incomplete filling, producing parts with uniform thickness and mechanical properties. This reliability is crucial for industries where precision and safety are paramount, such as medical devices, wearable electronics, and automotive components.

Adjustable material properties further enhance the versatility of liquid silicone injection molding. By modifying the formulation of liquid silicone rubber, manufacturers can control hardness, flexibility, and thermal resistance, enabling the creation of components that are soft, comfortable, and durable. The superior surface finish achievable through this process enhances both the aesthetic and functional value of the components.

applications of liquid silicone injection molding across industries

Liquid silicone injection molding has broad applications across multiple industries, reflecting its adaptability and reliability. In the medical field, it produces biocompatible components such as tubing, seals, and implants that withstand sterilization while maintaining structural integrity. The electronics industry uses this technology for flexible connectors, protective casings, and heat-resistant parts that safeguard sensitive devices.

The automotive sector benefits from vibration dampers, gaskets, and weatherproof seals made with liquid silicone injection molding, which endure extreme temperatures, pressure, and mechanical stress. Consumer goods such as kitchenware, personal care products, and flexible molds also leverage this process for enhanced safety, durability, and performance. Its versatility allows designers to innovate, producing intricate parts that conventional molding techniques cannot achieve.

technological benefits of liquid silicone injection molding

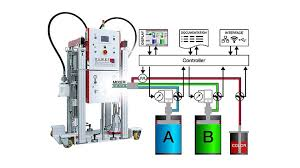

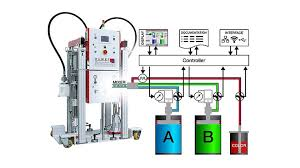

Advanced liquid silicone injection molding integrates modern technology to improve efficiency and quality. Computer-aided design (CAD) and simulation tools enable precise mold development and predict material behavior in complex geometries. Automated injection systems provide consistency, reduce human error, and support multi-cavity molds for high-volume production.

This technological integration facilitates rapid prototyping, allowing manufacturers to refine designs before full-scale production. High repeatability ensures that every part meets tight tolerances, reducing defects and material waste. The combination of technology and process control makes liquid silicone injection molding ideal for producing high-performance components efficiently and reliably.

choosing the right liquid silicone injection molding partner

Partnering with an experienced liquid silicone injection molding manufacturer is essential for achieving optimal results. Skilled manufacturers offer expertise in material selection, mold design, and process optimization, ensuring that components meet performance and quality requirements. Collaboration with a knowledgeable partner also accelerates development timelines, enabling rapid prototyping, small-batch production, and scalable mass production.

A reliable manufacturer can recommend design improvements, optimize production processes, and address challenges early, minimizing risks and ensuring consistent quality. Selecting the right partner is a key factor in maximizing the advantages of liquid silicone injection molding while reducing production costs and enhancing product reliability.

conclusion on liquid silicone injection molding

Liquid silicone injection molding is a versatile, precise, and reliable manufacturing process that delivers high-quality components across medical, automotive, electronics, and consumer goods industries. Its ability to produce intricate designs, maintain material properties, and ensure consistent product performance makes it an indispensable tool in modern manufacturing.

By collaborating with expert liquid silicone injection molding manufacturers, businesses can access advanced technology, achieve efficient production, and develop innovative, durable, and high-performance components. This process not only ensures product excellence but also enhances competitiveness, making liquid silicone injection molding a cornerstone of contemporary industrial manufacturing.

More Info: https://siliconemakers.com/