Thermal engineering plays a crucial role in modern manufacturing, influencing everything from product quality to production speed to long-term equipment reliability. As industries in India continue to grow at a rapid pace, so does the demand for precision heating systems, thermal simulation, and engineering support that ensures efficiency and consistency. Nexthermal has emerged as a trusted thermal engineering services provider in India, combining global expertise with local manufacturing insight to deliver end-to-end thermal solutions for diverse industries.

With more than 30 years of experience, Nexthermal has built its reputation on innovation, engineering excellence, and a deep understanding of customer applications. From custom heating elements to advanced temperature control systems, every solution is designed to solve a real-world thermal challenge.

Three Decades of Engineering Excellence

Over the last three decades, Nexthermal has partnered with global and Indian companies across manufacturing, automotive, aerospace, medical devices, packaging, plastics, and electronics. This extensive experience has helped us understand the evolving needs of industrial applications. Our engineering philosophy focuses on designing heating systems that not only meet technical requirements but also enhance operational efficiency.

Through our About Us expertise, we have consistently solved industry challenges such as temperature uniformity issues, inconsistent heat transfer, premature heater failures, and inefficiencies caused by outdated heating technology. This experience gives our team the ability to recommend accurate solutions faster, reducing trial-and-error cycles and improving time-to-market for customers.

Custom Heating Elements Designed for Performance

Nexthermal specializes in application-specific heating elements built to withstand the unique challenges of Indian industrial environments. Standard heaters often fail to deliver consistent performance when operating under fluctuating voltage, continuous production cycles, humidity, or material buildup. This is why Nexthermal engineers custom heaters built for reliability, efficiency, and durability.

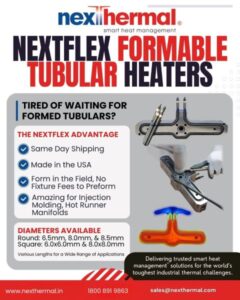

Our popular solutions include Cartridge Heater, Coil Heaters, and the next-generation NextFlex flexible heating technology. These heaters are engineered using advanced coil winding patterns, optimized heat transfer design, high-grade insulation materials, and manufacturing tolerances that ensure stable, predictable heating.

What sets Nexthermal’s heating elements apart is the engineering process behind them. Before manufacturing, we analyze load distribution, target temperature zones, heat-up time requirements, and environmental factors. This engineering-first approach ensures that every heater is tailored to its application, providing superior performance in demanding environments such as molding, sealing, packaging, and industrial processing.

Precision Temperature Controllers for Accurate Thermal Management

Even the most advanced heater cannot deliver optimal output without a reliable temperature control system. Nexthermal’s Controllers are engineered to provide precise temperature regulation, stable performance, and consistent heat delivery even under challenging power conditions.

Accurate control is essential for industries where minor temperature variations can cause defects, reduce quality, or impact safety. Our controllers are widely used in medical device production, food processing, aerospace components, packaging equipment, and injection molding applications.

Nexthermal’s control systems offer benefits such as faster response time, reduced temperature overshoot, energy-efficient operation, and seamless integration with existing machinery. When paired with Nexthermal heaters, they create a complete thermal solution designed for accuracy and repeatability.

Engineering Beyond Components: Complete Thermal Solutions

As a leading thermal engineering services provider in India, Nexthermal goes beyond supplying heaters and controllers. We provide complete system-level engineering, including thermal simulation, consultation, prototyping, and optimization.

Our thermal simulation services analyze heat flow, temperature distribution, warm-up time, and energy consumption. This allows our engineers to predict system performance before physical components are built. By identifying potential hot spots, cold zones, or inefficiencies early in the design stage, we help customers avoid costly redesigns.

We also provide full application support, from diagnosing existing thermal problems to improving cycle times, energy efficiency, and heater lifespan. Our engineering team collaborates with customers throughout the process, ensuring that each thermal system meets performance goals and industry standards.

Serving India’s Fast-Growing Industrial Sectors

Nexthermal supports a wide range of industries in India, many of which require highly precise temperature control and reliable heating systems. This includes plastics molding, packaging, aerospace, medical devices, electronics, automotive manufacturing, laboratory equipment, and food processing.

Bangalore, known as India’s engineering and innovation hub, plays a key role in our operations. With many high-tech manufacturing companies located in and around Bangalore, Nexthermal provides quick support, faster delivery, and application-specific engineering for customers in the region.

Our team’s deep understanding of local manufacturing challenges also allows us to design robust solutions capable of handling India’s climate conditions, power fluctuations, and heavy production cycles.

Why Nexthermal Is the Preferred Choice for Thermal Engineering Solutions

Customers choose Nexthermal because of our engineering-first approach, commitment to quality, and proven track record across global industries. Some key advantages include:

30+ years of thermal engineering expertise

Customized solutions tailored to each application

Advanced heating technologies such as NextFlex

Precision Controllers for stable performance

High-quality Cartridge Heater and Coil Heaters

Thermal simulation for optimized system design

Rapid prototyping and fast development cycles

Local support through our India engineering team

With this combination of capability and experience, Nexthermal delivers heating solutions that are reliable, efficient, and engineered for long-term performance.

A Trusted Engineering Partner for Your Thermal Needs

At Nexthermal, we believe in building long-term technical partnerships rather than simply supplying components. Our goal is to help customers improve product quality, reduce downtime, increase operational efficiency, and optimize energy usage through smarter thermal engineering.

Whether you need a custom heater, a temperature control system, or a complete thermal solution designed from the ground up, our team is ready to help. Connect with our experts through Contact or call 1800 891 9863 to discuss your application requirements.

Nexthermal is committed to engineering high-performance solutions that shape the future of India’s industrial heating landscape.

Book a Consultation: https://www.nexthermal.in/

Visit Product Page: https://www.nexthermal.in/engineering-services/

Connect With Us

More Products:

Electric Heating Elements manufacturer | cartridge heating element | coil heaters manufacturer | temperature sensors manufacturer | tubular heaters manufacturer | temperature controller manufacturers | Engineering services provider in india | Ceramic Infrared Heater manufacturer |Temperature Control Panel manufacturer | Heating Coil Element manufacturer | Tubular Heater manufacturer | Temperature Sensors manufacturer | Temperature Controller manufacturer