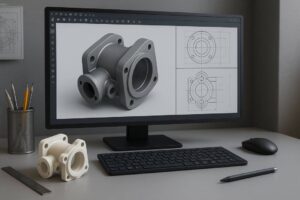

In an increasingly competitive world of engineering, manufacturing, and product design, precision and speed are not just goals, they’re necessities. That’s why more businesses are turning to 3D Modeling Services, especially solid modeling, to drive innovation and reduce risk. Whether you’re a startup or an established tech firm in the UK, USA or beyond, adopting solid 3D modeling can transform how you design, prototype and produce.

In this article, we’ll explore what makes 3D solid modeling services so powerful, how they streamline development, and what challenges and opportunities lie ahead for design-led companies collaborating with a 3D Modeling Company.

What Is 3D Solid Modeling and Why Is It So Valuable?

Solid modeling is a type of 3D CAD (Computer-Aided Design) where parts are represented as a full volumetric object not just surface outlines. These solid bodies carry data: volume, mass properties, material specifications, and more. By using 3D Modeling and Design services, companies can build models that are not only visually accurate but also engineering-ready for simulation, analysis, and manufacturing.

This capability matters because:

- It reduces the guesswork in design — designers can validate form and function before building a physical prototype.

- It supports downstream processes — patterns, CNC machining, 3D printing, and FEA tools can all consume precise solid models.

- It enables innovation — complex geometries, organic shapes or optimized structures become feasible.

- It improves collaboration — engineers, designers, and fabricators can review the same model and iterate faster.

How Do 3D Solid Modeling Services Boost Accuracy in Engineering?

- Rich Geometric Data

Solid models carry detailed information about volume, centres of gravity, and material thickness. This data ensures that parts will behave in the real world as they’re designed. - Design Validation & Simulation

Engineers can run simulations (like stress analysis or thermal load) directly on solid models, catching structural problems before production. - Interference Detection

When assembling multiple parts, solid modeling makes it easier to detect clashes and misalignments helping teams avoid costly re-work. - Parameter-driven Design

Many 3D Modeling Services use parametric modeling: design parameters (dimension, angle, curvature) can be adjusted and the model updates automatically maintaining design intent and increasing accuracy. - Seamless Manufacturing Handoff

Models can be exported in formats compatible with CAM (Computer-Aided Manufacturing) or CNC machinery, ensuring that manufacturing teams work with precise, fabrication-ready data.

How Does It Drive Innovation?

- Complex Geometry: Designers experiment with organic and biomorphic forms that were previously difficult to produce.

- Topology Optimization: With simulation and solid modeling, teams can design parts that maintain strength while minimizing material enabling lighter, more efficient products.

- Rapid Iteration: Designers can explore and validate radical ideas virtually, iterate quickly without physical prototypes, and test multiple design variants.

- Generative Design: AI-powered design tools generate optimized shapes based on performance criteria (weight, strength, material), which are then refined through solid modeling.

- Sustainability: Less waste, fewer prototypes, and more optimized structures contribute to more sustainable product development.

What Trends Are Fueling the Rise of 3D Solid Modeling Services?

- Growing CAD Market: The global 3D CAD software market is projected to reach USD 21.8 billion by 2033, driven by demand in manufacturing and engineering. (GlobeNewswire)

- Cloud-Based Collaboration: Real-time, cloud-based CAD platforms allow distributed design teams across the UK, USA and globally to co-develop models, improving speed and alignment. (Market Growth Reports)

- AI & Automation: Integrating AI into 3D modeling accelerates design generation and optimization, reducing time-to-market.

- Industry 4.0 & Digital Twins: Solid models become the core of digital twin strategies, linking design, production and operation.

- Sustainability Pressure: As companies push for greener operations, solid modeling helps reduce material waste and enables design-for-disassembly.

What Real-World Opportunities Does This Unlock?

For business owners, startups, architects, engineers, and tech leaders, 3D solid modeling offers tangible benefits and new strategic pathways:

- Faster Development: By validating designs virtually, you speed up iteration and reduce reliance on physical prototypes.

- Cost Efficiency: Fewer mistakes, lower material waste, and more accurate models mean lower development and production costs.

- Higher Quality Products: Simulation-backed design improves product robustness, reliability, and manufacturability.

- Scalability: Once you have parametric or generative models, scaling variants or custom designs becomes far easier.

- Innovation Differentiation: Use advanced modeling to differentiate your product line with complex, optimized forms.

- Global Engineering: Leverage a 3D Modeling Company to tap into global talent and distributed workflow, keeping development agile and collaborative.

What Challenges Should You Be Prepared For?

- Skill Gaps: Designers or engineers may lack deep experience in solid modeling or parametric techniques.

- Cost of Entry: Initial cost for software licenses, training, and creating high-fidelity models can be significant.

- Version & Data Management: As models evolve, keeping track of revisions, data integrity, and collaborative changes gets complex.

- Standardization: Without uniform modeling standards, different teams or partners may create incompatible models.

- Manufacturing Integration: Translating designs into production requires careful alignment so that solid models work seamlessly with CAM machines, CNC tools, or additive manufacturing systems.

- Intellectual Property Security: With cloud tools and shared models, data protection and IP management become critical.

How Can Businesses Get Started with 3D Solid Modeling Services?

Here is a practical roadmap for tech decision-makers, startups, architects or engineers:

- Define Your Goals

- Do you need improved accuracy, faster prototyping, or more creative freedom?

- Which parts of your product line will most benefit from solid modeling?

- Choose the Right 3D Modeling Company

- Work with a firm skilled in solid modeling, simulation and design-to-manufacture workflows.

- Ask for case studies relevant to your industry (automotive, industrial, consumer goods, etc.).

- Invest in Tools & Talent

- Pick CAD software that supports solid modeling, parametric design and collaboration.

- Train your existing team or hire solid model specialists.

- Pilot a Project

- Begin with a simple product to model and validate through simulation.

- Use the feedback to refine your processes and modeling standards.

- Embed Into Your Workflow

- Integrate solid models with production systems (CAM, CNC, additive manufacturing).

- Use models in cross-functional collaboration (engineering, design, manufacturing).

- Measure Impact

- Track key metrics: reduction in prototype iterations, design errors, time-to-market, cost savings.

- Use results to scale modeling services across more projects or product lines.

Who Stands to Gain the Most from Solid 3D Modeling?

- Manufacturers & Engineers: Accurate designs feed directly to production, reducing errors and waste.

- Product Designers & Innovators: Complex, high-performance parts become easier to conceptualise and validate.

- Startups & Bespoke Brands: Digital modeling enables rapid validation and iteration without heavy prototype costs.

- Architectural & Industrial Design Firms: Solid models help simulate structural behavior, fittings and materials.

- Tech & R&D Teams: Using digital twins powered by solid models for future innovation, IoT integration or smart manufacturing.

The Future of 3D Modeling Services Is Solid (Modeling)

As the world embraces Industry 4.0, 3D Modeling Services, particularly 3D solid modeling, are emerging as a linchpin for innovation, accuracy and efficiency. Businesses that adopt these services now whether through a trusted 3D Modeling Company or by building in-house capabilities gain a major strategic advantage. Solid modeling is no longer a “nice-to-have”; it’s a core part of modern design and development.

If you’re looking to future-proof your product development, consider partnering with a leading USA-based CAD modeling and design company. They can help you harness the power of solid modeling for rapid iteration, enhanced quality, and smarter manufacturing so your next product isn’t just built. It’s engineered to excel.