This article explores the broad versatility of pressure leaf filters, including the specialised molten sulphur leaf filter, analysing the key benefits, trade-offs, and critical considerations involved in their application.

The Wide-Ranging Applications of Pressure Leaf Filters

1. Edible Oil Processing

In the edible oil industry, pressure leaf filters are used to remove waxes, gums, and solids from oils like soybean, sunflower, and palm. Their ability to maintain product clarity and quality without contaminating the oil makes them a preferred choice. These filters help in achieving high filtration efficiency with low moisture and oil retention in the cake.

2. Molten Sulphur Filtration

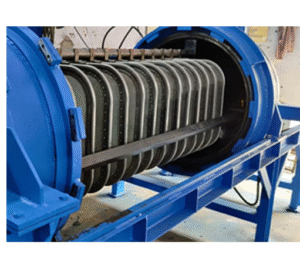

Molten sulphur leaf filters are specially designed to operate under high temperatures and corrosive conditions. Filtering molten sulphur is a critical step in fertilizer production, petrochemical refining, and chemical manufacturing. These filters effectively remove ash, iron, and dirt, ensuring the sulphur meets the purity standards required for downstream applications.

3. Fine Chemicals and Pharmaceuticals

The pharmaceutical and fine chemical sectors demand absolute clarity and sterility. Here, pressure leaf filters help remove suspended solids from high-value liquids while preserving their chemical integrity. Stainless steel construction and optional heating jackets enable compatibility with sensitive chemicals.

4. Petrochemical and Paint Industries

In the petrochemical sector, leaf filters remove solid contaminants from fuels, lubricants, and waxes. In the paint industry, they assist in the filtration of pigments and resins, contributing to product consistency and smooth finish. Their closed system ensures operator safety and minimal exposure to hazardous fumes.

Advantages and Trade-Offs of Pressure Leaf Filters

Advantages:

-

High Filtration Area in a compact footprint

-

Batch or Continuous Operation depending on process needs

-

Minimal Manual Intervention and reduced labor costs

-

Ease of Cake Discharge through vibration or reverse flow

Trade-Offs and Challenges:

-

Initial Setup Cost can be high, especially with automated systems

-

Not Ideal for High-Viscosity Liquids unless customized

-

Maintenance of internals and seals in high-corrosion environments like molten sulphur leaf filter systems

-

Operator Skill Requirement for optimizing backwash and cycle time

Key Factors Impacting Performance

-

Nature of Feed Material: Solid load, temperature, and chemical composition affect filter choice and configuration.

-

Filter Media Selection: Impacts filtration precision and reusability. For molten sulphur, special corrosion-resistant materials are needed.

-

Automation Level: Affects operational cost, efficiency, and process control.

-

Filtration Cycle Time: Balancing cycle duration with throughput to ensure quality and minimize downtime.

Why Versatility Matters in Filter Selection

When choosing between different industrial filtration solutions, businesses must weigh the specific needs of their process against the capabilities of available technologies. The pressure leaf filter offers unmatched versatility for companies operating in multiple sectors—allowing a single filtration technology to serve vastly different processes, from edible oil purification to molten sulphur filtration.

Failing to consider industry-specific challenges—like thermal resistance in sulphur or food-grade compliance in oils—can result in reduced performance or product contamination. A tailored approach ensures long-term efficiency, safety, and cost-effectiveness.

Conclusion

The adaptability of pressure leaf filters makes them an indispensable part of modern industrial filtration systems. Whether you’re clarifying edible oils or filtering molten sulphur, their robust performance, efficiency, and scalability offer a competitive advantage across sectors. With proper configuration and maintenance, these systems can deliver consistent results for years.

FAQs:

Q1. What is a pressure leaf filter, and how does it work?

A pressure leaf filter is a type of filtration system where liquid passes through vertically or horizontally arranged filter leaves to separate solids. It’s ideal for applications requiring high throughput and clarity.

Q2. Why is a molten sulphur leaf filter different from regular pressure filters?

Molten sulphur filters are built with heat-resistant and corrosion-proof materials to handle high temperatures and reactive elements found in sulphur.

Q3. Can pressure leaf filters be used in the food industry?

Yes, they are widely used in edible oil processing due to their closed design, hygienic operation, and compliance with food safety standards.

Q4. How often do pressure leaf filters require maintenance?

Maintenance frequency depends on the process, but regular inspection of the filter media, seals, and discharge systems is essential for optimal performance.

Q5. What industries benefit most from pressure leaf filters?

Industries like edible oil refining, fine chemicals, pharmaceuticals, petrochemicals, and sulphur-based production processes benefit from the versatility of pressure leaf filters.